Promotional Features

Natural blues: Using spirulina concentrates to achieve vibrant confectionery colors

Blue is widely used as a color throughout the sugar confectionery industry.

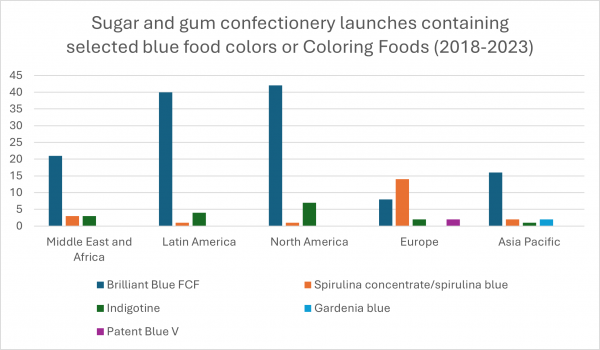

Many manufacturers outside Europe use color additives such as Brilliant Blue FCF (Blue 1) – an artificial colorant made from an oil base – to achieve bright and stable shades. However, rising global concerns around the potential health impacts of artificial colors are now driving increased interest in natural alternatives.

Several plant-based blue colors have been created in recent times based on a variety of pigments. At present, those containing water-soluble phycocyanin pigments stand out for their vibrancy and ability to replace Brilliant Blue FCF.

Spirulina (Arthrospira platensis) is a blue-green edible algae that has been consumed for a long time within Europe and around the world as a food or functional food. Spirulina concentrates have become the most popular option for plant-based blue shades in sugar and gum confectionery launches on a global level.

Spirulina concentrates can also be combined with a concentrate of yellow raw materials to deliver a spectrum of greens, from turquoise to lime to emerald. Mixing spirulina concentrates with concentrates of red raw materials, meanwhile, will deliver violet hues.

Source: Mintel ‘Patent insights: emerging food colour innovations’ (January 2024).

Technical factors

Spirulina concentrates can deliver excellent results in the vast majority of confectionery applications. However, as phycocyanin is a protein-structured pigment, it is important to manage its sensitivity to acid and temperature.

Most confectionery applications are acidic, often featuring pH levels around 3, while many require high processing temperatures. The phycocyanin pigment can be denatured with an excess of either acid or heat, resulting in color degradation, coagulation, and agglomeration of particles. This can mean the end product appears less vibrant, develops more of a teal appearance, or features blue specks.

However, there are various ways to overcome these challenges and get the best out of spirulina concentrates in confectionery. The application examples below have been created using GNT’s EXBERRY® spirulina concentrates as the reference ingredient.

Gummies

It is important to minimize heat exposure as much as possible for optimal results. For starch, pectin, and gelatin gummies, the most vibrant blues are achieved when adding the color at temperatures below 97°C/207°F, with even deeper blues at temperatures under 90°C/194°F.

Manufacturers should also avoid holding the colored syrup for any period at more than 65°C/149°F. Once the spirulina concentrate is well dispersed into the gummy mass, acidic ingredients can be added before depositing. Specific ingredients, like vitamin C or fruit juice that contribute yellow tones in the gummy mass, can increase the dosage of blue needed to achieve a true-blue hue rather than a blue-green shade.

Hard-panned confectionery

Pastilles, dragées, and tablets tend to have a neutral to slightly acidic pH level, so acid is not a major issue, and do not usually present significant issues with heat. However, hard-panned applications do present other challenges. One common issue is the tendency for hard-panned confectionery pieces to become sticky and adhere to each other when invert sugar is used as a carrier for the color.

Because invert sugar does not recrystallize when cooled, it leaves a tacky surface. The EXBERRY® HP range uses sucrose as a carrier instead. In contrast to invert sugar, sucrose recrystallizes, which makes it ideal for this process.

Chocolates and compound coatings

It can be difficult to achieve homogenous color effects in fat-based applications such as chocolate. As such, micronized powders or oil-dispersible colors featuring a smaller particle size should be used to allow for an even distribution. EXBERRY® MN powders are made with a unique multi-stage milling process that means the average (D50) particle size is below 20μm, in comparison to an average of around 50μm for standard powders.

EXBERRY® OD colors are made by dispersing the smaller particles in oil for a liquid-based alternative. In terms of heat, manufacturers should avoid base temperatures above 45°C/113°F to help protect the phycocyanin. The temperature of oil-dispersible colors should also be as close to that of the base product as possible.

Aerated confectionery

It is possible to achieve attractive blue and green shades in products such as gums, pulled chews, and marshmallows. In highly aerated products, paler, more pastel results will be achieved. The density of the candy will also affect the amount of color required, with more air incorporation requiring a higher dosage.

The application temperatures should ideally be no higher than 75°C/167°F and temperatures above 95°C/203°F should be avoided. The pH value of aerated products is limited to a range of around 4 to 6. This is because higher levels can weaken the protein matrix responsible for trapping air bubbles and can interfere with the stability of the aerated structure.

Pressed tablets

Applications such as mints and comprimates tend to have a neutral to slightly acidic pH level and are created through the use of pressure. As such, acidity and heat are not significant concerns. Standard spirulina powders can be used in pressed tablets to achieve speckled blue and green shades. If a homogenous appearance is required, micronized powders should be used to allow for an even distribution of color throughout the tablet. The appearance and color intensity will also be influenced by the pressure applied in the press.

Spirulina concentrates offer a high-performing source of natural blues, but they are not a plug-and-play solution and additional challenges can arise around issues such as ingredient interactions. Brands should therefore work with a supplier that can provide complete technical support on color selection, stability testing, performance, and upscaling.

Labeling spirulina

GNT pioneered the first blue Coloring Foods made from spirulina concentrate in the early 1990s. Coloring Foods are produced using physical processes and no chemical solvents, with no selective extraction of the pigments relative to the nutritive and aromatic constituents.

Within the EU, spirulina-based Coloring Foods can be described on the ingredient list of the final product as ‘Coloring Food (concentrate of spirulina)’ or ‘Concentrate (spirulina).’ This is also the case in many countries around the world.

Within the US, spirulina-based Coloring Foods are classed as permitted color additives, which can be used for coloring confections and described on the ingredient list of the final product as ‘Spirulina Extract for Color’ or ‘Spirulina Extract (Color).’

Spirulina: Consumer appeal

Spirulina concentrates are plant-based colors that allow manufacturers to create visually attractive blue confectionery without the use of artificial colorants. Spirulina has become increasingly familiar to consumers around the world, both as a coloring ingredient and as a popular superfood, helping to maximize product acceptance.

As demand for natural coloring solutions accelerates, spirulina concentrates provide confectionery manufacturers with a proven source of vibrant, stable blues and greens that can be used to eliminate artificial colorants from the ingredient list.